Are you ready to dive into the world of metal cutting? Whether you’re a seasoned professional or a DIY enthusiast, knowing how to cut through metal efficiently and effectively is a valuable skill. In this guide, we’ll explore various methods, tools, and factors to consider when tackling metal-cutting projects.

At Saxton Blades, we offer a range of metal saw blades that cut through a variety of different metals. From Metal Circular Saw Blades to Multi-Tool Saws, we have something for everyone →

What Saw Cuts Metal?

When it comes to what cuts metal, there’s no shortage of options. From traditional hand tools to advanced machinery, the best tool to cut metal depends on factors such as the type of metal and thickness of the metal, the desired cut quality, and the available equipment. Below you will find a range of saws that cut through metals.

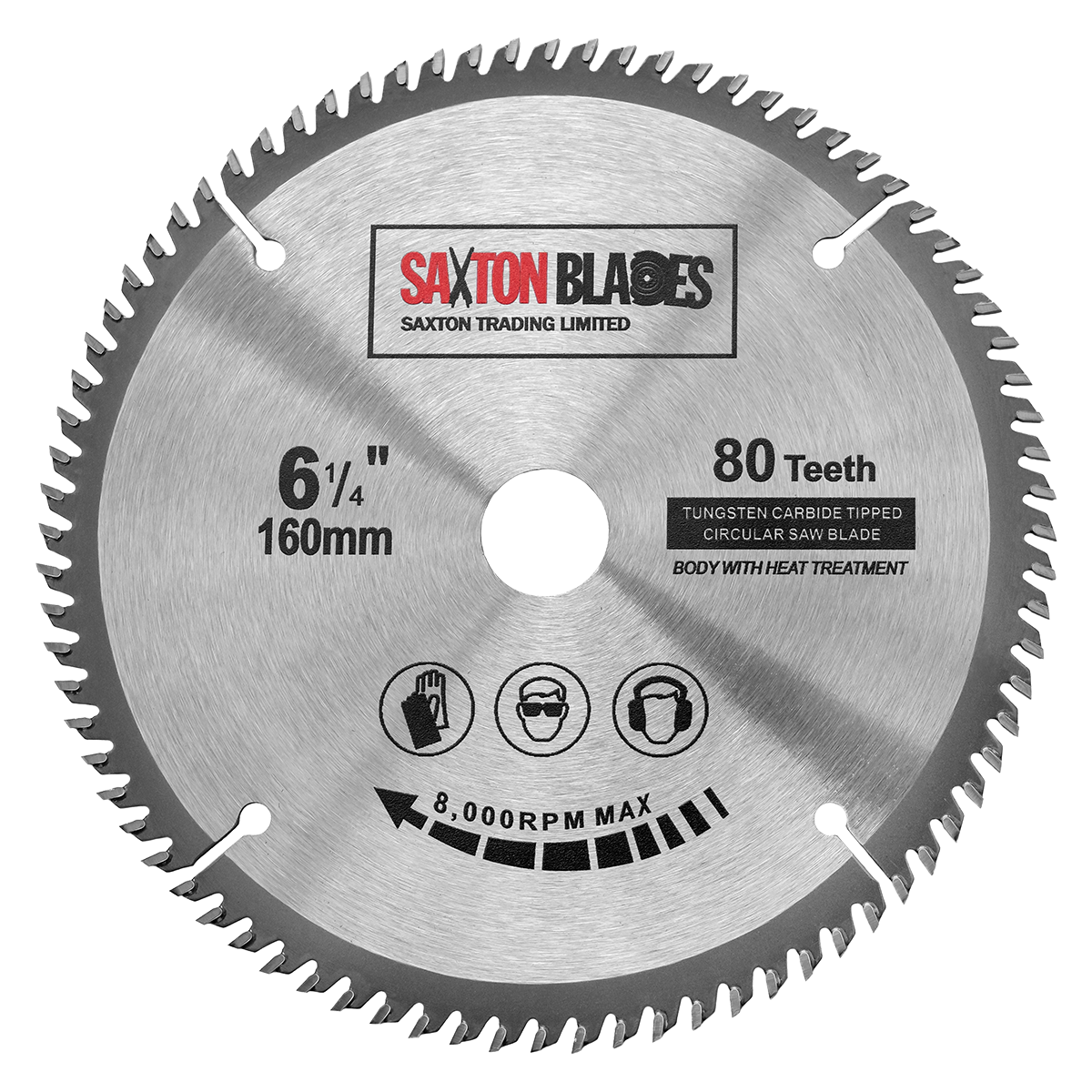

Circular Saw:

Although commonly known for cutting through wood, a circular saw is also extremely beneficial for cutting through many different materials, including metal.

With the right circular saw blade, it can produce a clean, precise cut-through sheet metal, rebar, and ⅜ inch stock. For the best results, opt for a metal cutting blade.

Shop our range of circular saw blades to cut through metal.

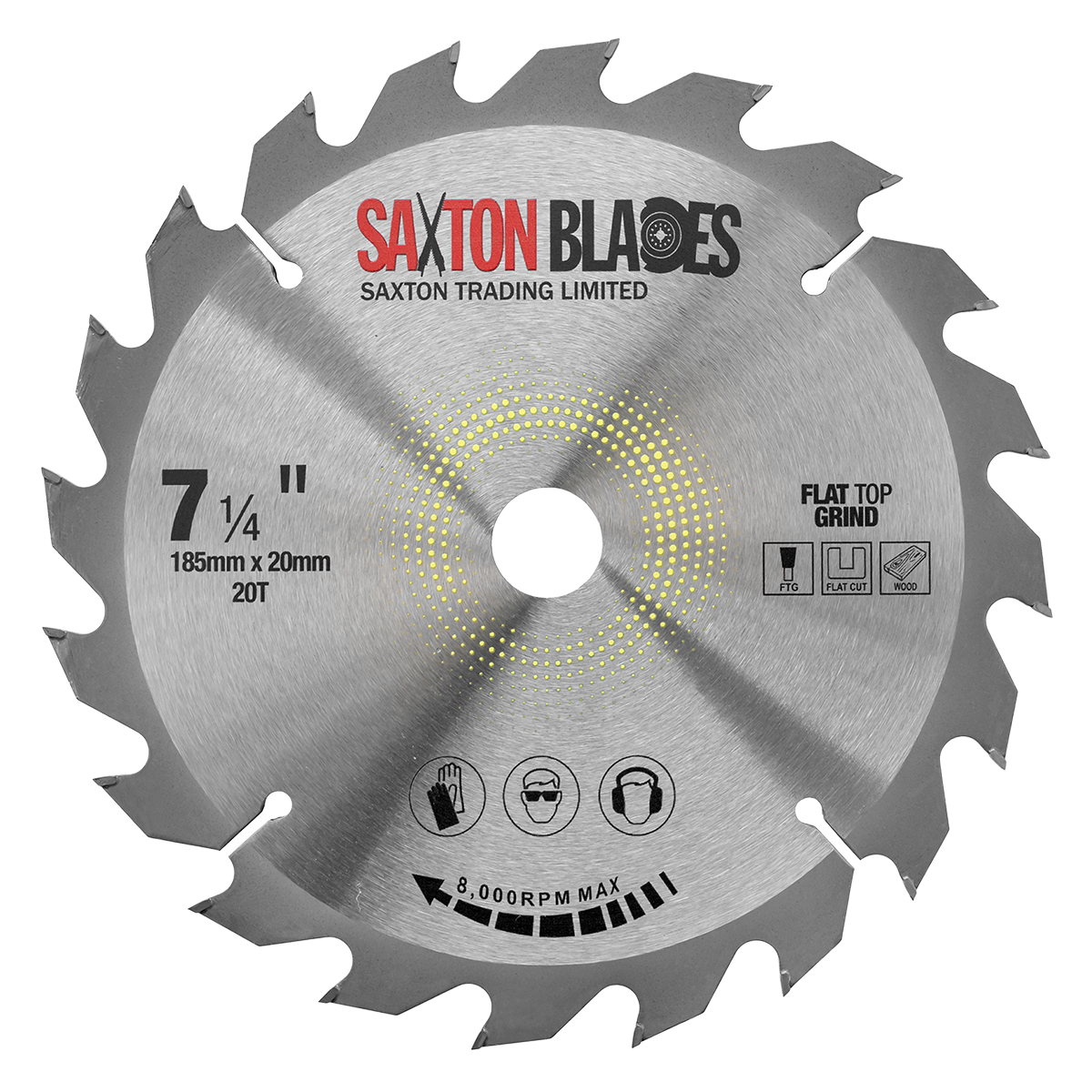

Miter Saw:

When it comes to cutting through metal, a mitre saw is a metal cutting tool that works very similarly to a circular saw. However, due to their special arm-based, they can cut at more of an angle.

If you are looking at how to cut through metal with a mitre saw, there are some factors to take into consideration.

Due to the power of the saw, it can lead to thinner metal sheets bending during the cutting process. To avoid this, we recommend using a wood backing to offer stability when cutting. When cutting metal, do not exceed the max rpm stated on the blade.

Multi Tool Saw:

If you are looking to make flush cuts through a variety of metal fittings such as steel pipes, nuts, and bolts, an oscillating tool is an ideal metal cutting tool to have in your arsenal.

Just as the nature of their name, a multi-tool comes with a variety of blade heads, choose one that is specific for cutting metal. But it is important to remember that this tool wasn’t designed to specifically cut through metal. Make sure to clamp any materials to prevent any movement.

Browse our range of metal blades for multi-tools →

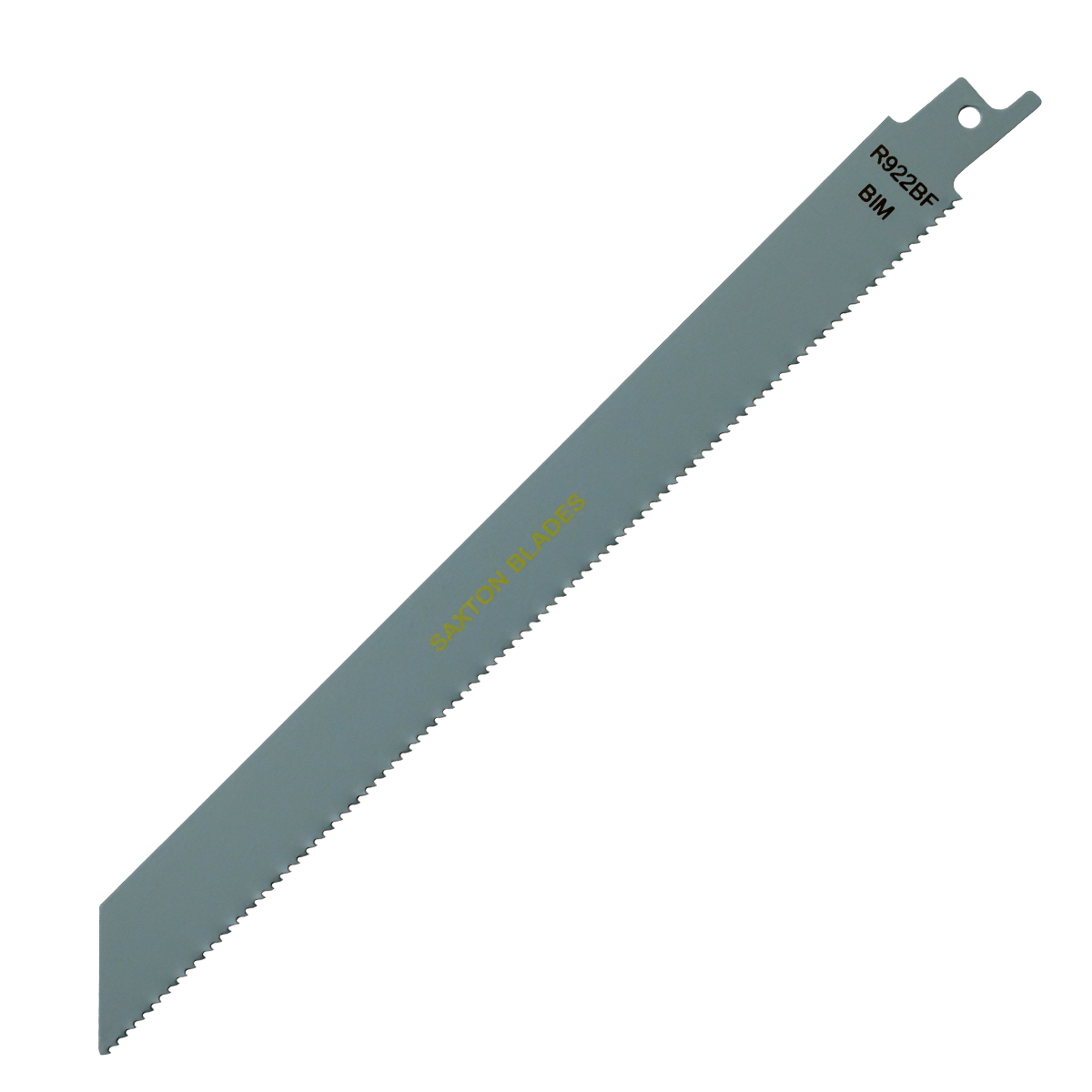

Reciprocating Saw:

One of the more affordable options is a reciprocating saw an adaptable and dependable metal cutting tool that is mainly beneficial for DIYers. Reciprocating saws are great for cutting through general metal stock that is found in general projects, rather than heavy-duty metal stock.

Ultimately, it’s essential to have the correct blade for the job.

Get your Reciprocating Saw Blade for metal cutting today

Jigsaw Blade:

While primarily used for cutting wood, jigsaws can also be equipped with metal-cutting blades to make curved or intricate cuts in thin metal sheets or softer metals like aluminium. They offer manoeuvrability and control, making them suitable for detailed metal-cutting tasks.

Take a look at our full range of jigsaw blades for metal cutting

Other Factors To Consider When Cutting Metal

While choosing the right cutting tool is essential, several other factors can influence the success of your metal-cutting project.

Environment

Making sure you’re working in the right environment is paramount. Ensure you’re working in a well-ventilated area with proper safety equipment to protect yourself from fumes, sparks, and debris. Consider using a workbench or sawhorse to stabilise your workpiece and prevent accidents.

Proper Technique

Familiarise yourself with the proper usage of your chosen cutting tool, including blade positioning, speed, and feed rate. Follow the manufacturer’s instructions and safety guidelines to ensure safe and efficient cutting.

Blade Selection

Match the blade to the type and thickness of the metal you’re cutting to ensure optimal performance and results. Choose a blade with the appropriate tooth count, tooth geometry, and material composition for the best cutting performance.

Safety Precautions

Always wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection, when cutting metal. Avoid wearing loose clothing or jewellery that could get caught in the cutting tool, and be mindful of your surroundings to prevent accidents.

Practice and Patience

Cutting metal requires practice and patience to master. Start with small projects and gradually work your way up to more complex tasks. Don’t rush the process, and always prioritise safety.

How To Cut Metal: Step by Step

- Prepare Your Workspace: Choose a well-ventilated area with proper lighting and clear of clutter. Secure the metal workpiece on a stable surface.

- Wear Personal Protective Equipment (PPE): Put on safety glasses, hearing protection, and heavy-duty gloves to shield against sparks and debris.

- Select the Right Tool: Choose the appropriate cutting tool for the metal type and thickness, such as an angle grinder or a circular saw.

- Secure the Workpiece: Clamp or secure the metal firmly to prevent movement during cutting.

- Follow the Manufacturer’s Instructions: Familiarise yourself with the tool’s operation and safety guidelines before starting.

- Make Controlled Cuts: Guide the tool steadily along the cutting line, avoiding excessive force or sudden movements.

- Monitor Cutting Progress: Stay clear of sparks and debris, and inspect the cut for smoothness and accuracy.

Shop At Saxton Blades To Cut Metal With Precision

By understanding the various cutting methods available and considering important factors such as tool selection, safety precautions, and proper technique, you’ll be well-equipped to tackle any metalworking project with confidence.

Shop our full range of metal cutting blades available at Saxton Blades →