To make smooth and safe cuts with your saw, it’s important to choose the right type of blade. The type of blade you need will depend on a few things including the type of cut you’re trying to make and the material you’re cutting into. Choosing the right blade will give you better control and precision, and will have a much better lifespan too.

When choosing a saw blade, there are a few things you should consider such as blade size, number of teeth, carbide grade of type, the hook angle and tooth configuration. It can be confusing to know which blade is the right one when there are so many out there to choose from. In this guide, we’ve run through exactly how to choose the right blade for your type of saw and the project you’re working on.

How to Choose a Circular Saw Blade

Circular saw blades are discs with teeth that can cut a range of materials using a spinning motion. They can be fitted to power saws cutting many materials such as wood, masonry, plastic, or metal. Most circular saws come standard with a 7¼-inch-diameter blade and a motor that draws 8 to 15 amps of power.

There are a few things to consider when choosing your circular saw blade. These include:

- The type of material you’re cutting

- Tooth type

- The bore

- Blade thickness

- Depth of the cut

- The material of the blade

- Number of teeth

- The number of revolutions per minute (RPM)

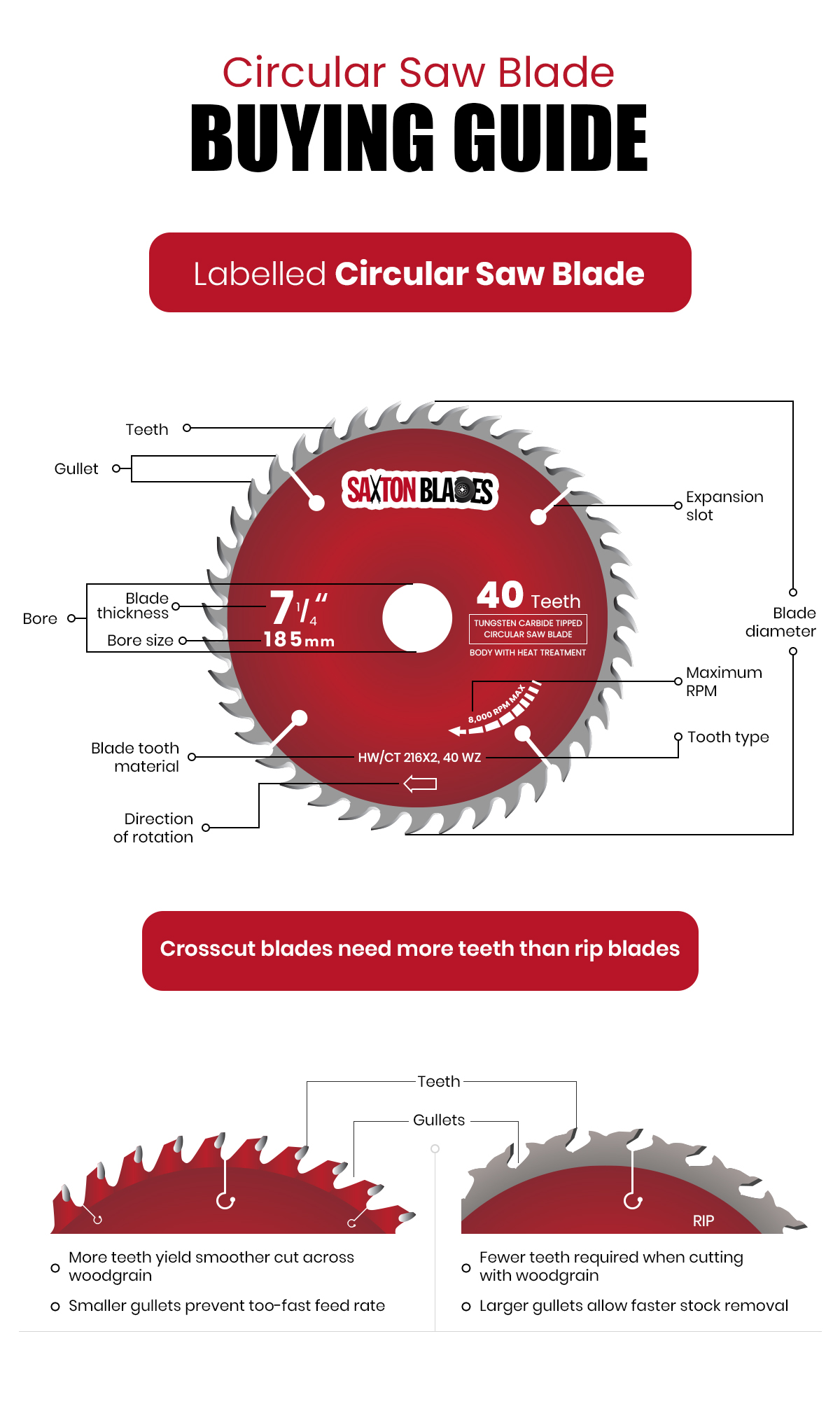

Blade Diameter:

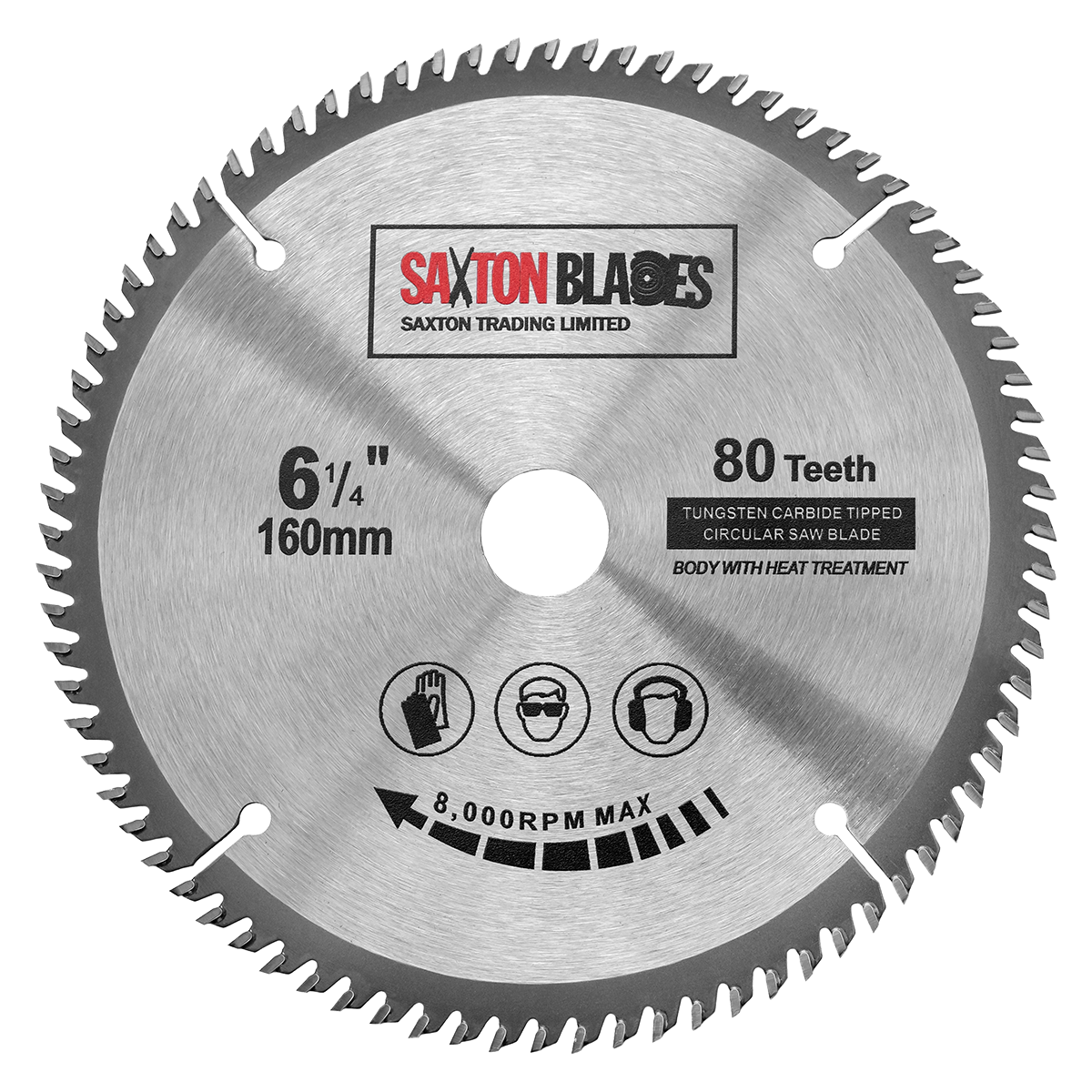

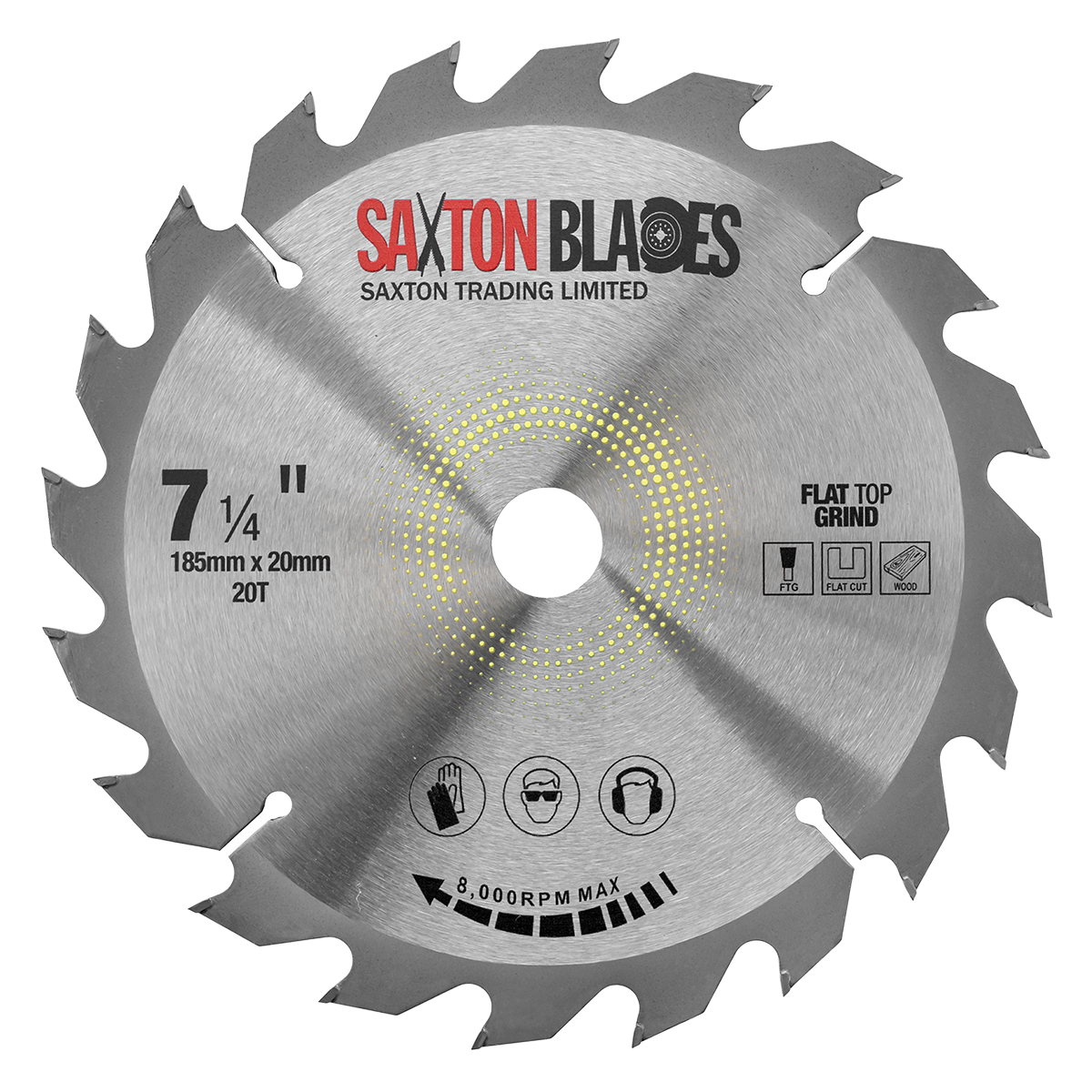

For safety reasons, it’s very important that the blade is the correct diameter for your cutting requirements and the specific RPM (speed) of your blade and saw. This means that the diameter of the saw blade you select must not exceed the maximum diameter of the blade designed to use with your saw. When selecting your blade, be sure to carefully read the measurements of the label and to check the requirements of your power tool. The blade diameter will usually be printed on the face of a circular saw blade, along with the arbor hole size, number of teeth and kerf (the thickness of the cut the blade creates)

The Number of Teeth:

TLDR; More teeth: Smoother, finer cut. Fewer teeth: Faster, rougher cut.

The correct number of teeth is important to ensure that you achieve a smooth cut with optimal chip removal and as little friction possible whilst sawing. The correct number of teeth will also place less strain on your equipment, extending the lifespan of your power saw.

Generally, blades with fewer teeth will cut through materials faster, but blades with more teeth will create a finer finish and smoother cut. For example, a typical 10-inch rip blade that is designed for ripping up lumber might have just 24 teeth. The aim of the blade is to quickly remove material along the length of the grain. The blade isn’t designed to yield a mirror-smooth cut, instead, it will move through hardwood with little effort and leave a clean cut with minimal scoring.

A crosscut blade, on the other hand, is designed to produce a smooth cut across the grain of the wood, without splintering or tearing. This type of blade will usually have 60 to 80 teeth, and the higher tooth count means that each tooth has to remove less material. A crosscut blade makes many more individual cuts as it moves through the stock than a ripping blade and, as a result, requires a slower feed rate. The result is a cleaner cut on edges and a smoother cut surface. With a top-quality crosscut blade, the cut surface will appear polished.

The Gullet:

The gullet is the size of the space between the teeth on your saw blade. When choosing a blade, the gullet is equally as important as the number of teeth on the blade. This is because a smaller blade with fewer teeth might have the same gullets as a larger blade with more teeth. For example, a 130 mm blade with 24 teeth will have the same gullets as a 260 mm blade with 48 teeth. So it’s important to take both into consideration. The size and depth of the gullet determine how much waste material is cleared out as the blade spins.

The Size of the Teeth:

Blades with larger teeth spaces further apart are ideal for making rip cuts (cuts made in woodworking to sever a piece of wood parallel to the grain). This is because large spaces between the teeth (gullets) allow the sawdust to be expelled quickly. Smaller teeth, on the other hand, allow for a better finish, so are ideal when making crosscuts (cutting across the grain of the wood or material).

The Hook or Rake Angle:

The angle of the hook or rake refers to the position the blade tooth is in when it hits the cutting surface. Hook angles can be positive, negative or neutral.

A positive hook angle points downwards towards the cutting surface, creating a faster and rougher cut. For some cutting applications such as metal cutting, a positive hook can be dangerous. A more negative hook angle will provide a less aggressive cut and create a smoother finish. This will be a slower cut that removes less waste, however. A neutral hook angle means that the face of the cutting tool is perpendicular to the cutting edge at the inner side.

The Size of the Bore:

The bore is the hole at the centre of your saw blade, which is where you attach the blade to your saw. You can select a saw blade that with a bore that has a higher diameter than the bore shaft of your saw, however, you must use a reducer ring to get the right fit.

Shop Affordable Circular Saw Blades

If you need affordable and high-quality circular saw blades compatible with all major brands of circular saws including Makita, Bosch, and Dewalt. Our blades are of the same excellent quality, but available for a fraction of the price you’d pay elsewhere.

We also offer FREE UK delivery on all orders over £10. Get great deals on circular saw blades today.